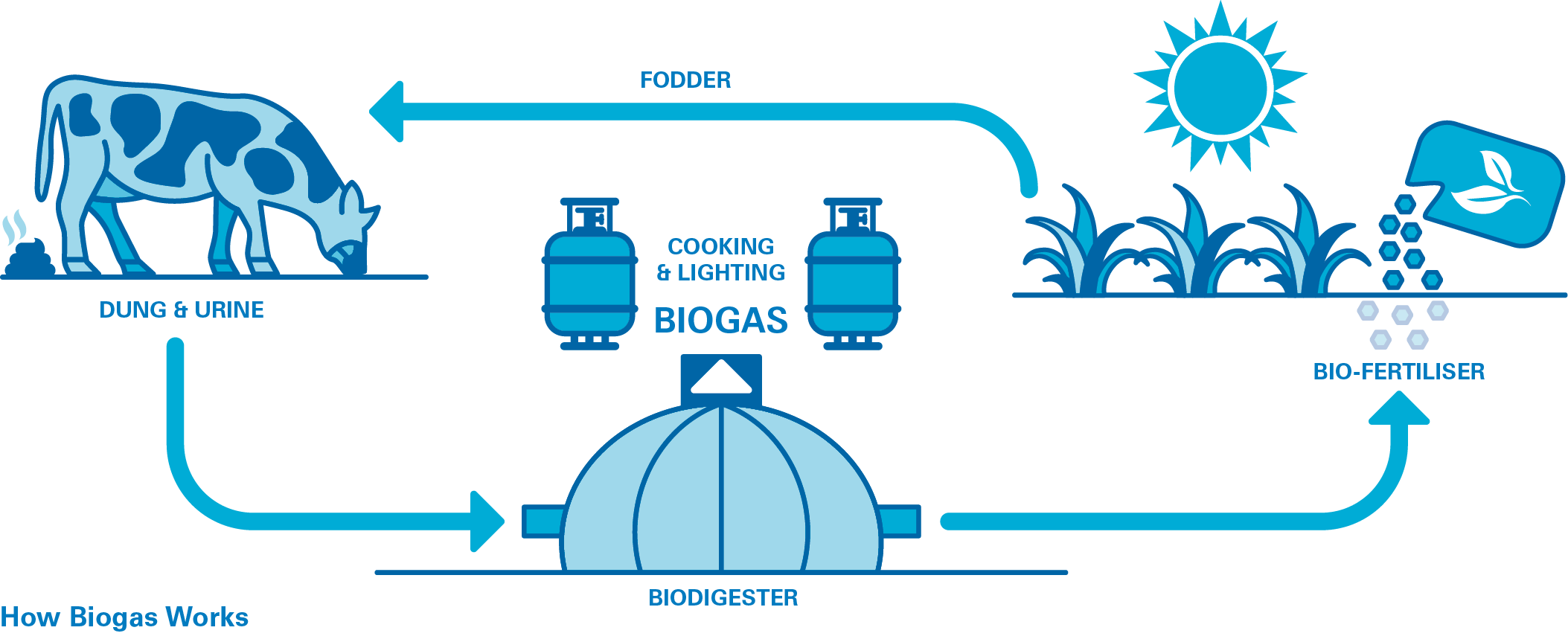

The generation of electricity and heat are typically the primary uses of biogas.

Biogas can be used for many different things however the generation of electricity and heat are typically the primary uses. Additionally, biogas can be purified to remove carbon dioxide and other trace gasses. This is often called biomethane and can then be injected it into the mains gas grid or used as a road fuel.

As the process of AD requires some heat to process the organic waste it is suited to Combined Heat and Power (CHP) applications and this is currently the most popular option for most installations. CHP plants can achieve overall efficiencies in excess of 80% at the point of use. The ratio between heat and power varies depending on the scale and technology used but typically 35-40% is converted to electricity, 40-45% to heat and the remainder lost as inefficiencies in the process.

AD is not a new technology and has been used since the 1800s. However, an increasing number of AD plants are being built to generate clean renewable energy. Additionally, AD is also increasingly used to treat the waste produced in homes, farms, supermarkets and industries and helps divert organic waste from landfill

On average, Cattle slurry with 10% dry-matter weight has the potential to produce between 15 and 25 cubic meters of Biogas per Tonne of waste. Over the course of a year, an average cow can produce around 16 tons of slurry. One cubic metre of biogas comprising 60% methane contains 6.7 kWh energy. This typically equates to over 2kWh electricity and 2.5kWh heat per cubic metre when used for combined heat and power applications. In addition, the by-product (known as digestate) from a well-controlled and maintained biogas system is a mineral and nitrogen rich fertiliser that can be used to enhance plant and crop growth.

AD systems vary greatly in price depending on feedstock and complexity. Despite relatively high capital costs, payback times for installations tend to be short largely due to high avoided costs of waste disposal.